V Fold Facial Tissue Paper Folding And Making Machinery For Sell

The whole line is with Facial tissue machine, conveyor, facial tissue log saw cutting machine and plastic film packing machine

Description

Automatic Facial Tissue Paper Making Machine And Processing Machine is with the functions of embossing, slitting, folding, counting, and dividing,auto-taking, auto-transporting, auto packing in one, which the whole production process is fullfiled automatically. this production line has the advantages of simple operation,high production efficiency, and keeping the consistent of the finished products, with the fully automatic production, the amount of production labour can be reduce, so to save the production and managing cost greatly.

Features:

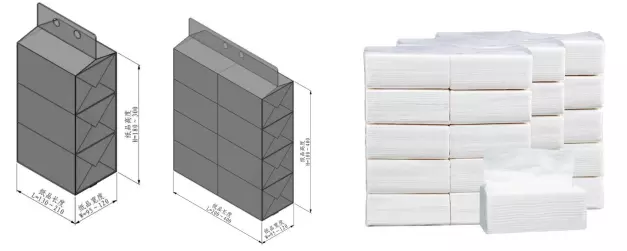

Facial tissue making machine working flow:The jumbo rolls which have been slit into the desired width are cut by the slitting cylinders,and then interfolded into interoverlapped rectangular facial tissue sheets.

This machine adopts independent servo motor drive,and automatic paper tension control automatic marking functings.It featurse of high speed,nice folding and easy operation.

1 . Can order steel to rubber embossing rolls,pneumatically separated.

2 . Wallboard rack and Machine running stability and extremely good and fast.

3 . Pneumatic jumbo roll loading,pneumatic paper driving,stepless speed additionstment,and web tension control.

4 . Equipped with roots type vacuum pump for stable running of the machine.

5 . Make various products width as requirement.

6 . Equipped with edge embossing unit to keep the plise together.

7 . The machine will stop when the paper broken.It avoid waste caused by no paper or paper broken.

8 . The web can be threaded on the machine by the two jog buttons,It's more safer and easier to thread the web.

1. Specification of Facial Tissue Folding Machine:

| Machine Model | SYM-190/6L (Other size to be specified) |

| Finished Products Unfolded Size | 95x(120-210)x2mm |

| Folding Products Size | 190x(120-210)x2mm |

| Raw Material Width | 1260mm |

| Raw Material Diameter | 1200mm |

| Raw Material Core Diameter | 76.2mm |

| Output Capacity (8 hours) | 2000-3000kg |

| Embossing Unit | Steel to rubber |

| Edge Embossing | Steel to steel edge embossing, independent pneumatic regulation |

| Slitting Unit | Pneumatic slitting |

| Main Servo Moter Power | 5.5kw |

| Unwind Frequency Motor Power | 1.5kw (2 units) |

| Vacuum System | 18.5 kw Vacuum pump (Taiwan Roots blower) |

| Pneumatic System | 3HP air compressor,Min. pressure 5kg/cm2PA (Provider by user themselves) |

| Driving System | Timing belt |

| Dimension | 5870x2800x2207mm |

| Weight | About 5 tons |

2. Specification of Single Channel Log Saw Cutting Machine:

| Designation | Parameter values |

| The length of the none cut off facial tissue | minimum 500mm |

| The Height of tissue | 30~130mm |

| Machine Speed | 20~150cut/min |

| Operating speed | 20~120cut/min |

| Round blade outer diamete | Φ610mm |

| Paper cutting circular knife top speed | 980R/min |

| Finished products specification | 70~300mm |

| Paper width | 70~110mm |

| Cutting Length | 70~300mm |

| Left-over Length | 20~65mm |

| Power | 11KW |

| Power supply | 380V 50Hz |

| Air source | 0.5~0.8MPa |

| Machine Size | 4600*1700*2500mm |

| Weight of machine | 2300~2600kg |

| Brake | Parameter setting (auto/manual) |

| Stepping sharpening knife | Parameter setting (auto) |

| Pneumatic sharpening knife | Parameter setting (auto/manual) |

| Blow air | without |

| The total pressure switch | Value (not) |

| Human-computer interface | DELTA |

| Frequency changer | |

| Servo Drive | DELTA |

3. Specification of Facial Tissue Packing Machine:

1 . Adopting packing way by wrapping, folding and sealing with compact structure, it makes the package look beautiful and the seal tightened.

2 . Controlled by stepless speed regulation, touch screen and PLC, the display on the human-machine interface makes maintenance more simply.

3 . Applied with auto-arranging feeding conveyor, it is convenient to connect the conveyor with automatic production line, saving the labor cost to the maximum.

4 . It saves much packing material by means of photocell checking, servo tracking, and auto-stop of film feeding without product.

5 . High automation, high profession, high efficiency and less trouble.

6 . With wide packing size range, various packing sizes can be quickly interchanged.

| Tissue sizes: | L: 150-400mm W: 150-200mm H: 35-150mm |

| Packing speed: | 40-70 bags/min |

| Air supply: | 0.5-0.8MPa |

| Machine weight: | 3300kg |

| Outer dimensions (LxWxH): | 5885x3560x1925(mm) |

| Heating power: | 3.6kw |

| Motor power: | 3.6kw |

| Packing size: | ≤230x190x100(mm) |

| Working noise: | ≤78dB |

| Packing film: | CPP |

| Power supply type: | 380V, 50Hz |

4.Specifications of Semi Automatic Two Outlets Multi Bags Packing Machine:

| Packing Size | ≤500x300x110mm (LxWxH) |

| ≥220x120x90mm (LxWxH) |

| Packing Speed | 10-20 bag/min |

| Gas Pressure | 0.5mpa-0.8mpa |

| Voltage & Frequency | 380V,50Hz,3Phase |

| Total Power | 0.8kw |

| Weight | 1000kg |

| Overall Dimension | 4900x1650x1280mm |

| Tissue paper bag (one row/two rows) | Tissue paper bag (one row/two rows) |

Packing & Delivery

Our Company

SYM Shenzhen Yushengda Machinery & Engineering CO.,LTD

SYM SHENZHEN YUSHENGDA MACHINERY & ENGINEERING CO.,LTD, is emerging as a global leader in tissue converting and packing

machinery, backed by experience in machine design, manufacturing,

and service, we are uniquely equipped to provide our customers with

a wide range of innovative solutions. The range of tissue

converting machinery:

- SYM FOLD Conversion Range

- Napkin conversion. 1/4, 1/8, Dispenser Fold & Custom fold;

- Facial Tissue conversion. V fold interfold;

- Hand Towel conversion. V, Z, C & Multifold.

- SYM WIND Conversion Range

- Toilet Tissue & Kitchen Towel conversion rewinders;

- Industrial Roll conversion rewinders;

- SYM-Cut Log Saw for roll products.

- SYM MATIC Range

- Automatic Packing machines;

- Automation & Product Handling solutions.

Our commitment is to bring significant enhancements in our

productivity and responsiveness to the market, while improving the

quality of products and services we offer to our customers. We lead

new research and development ideas in the tissue market.

We at SYM deliver the best installation, start-up, training, and

maintenance performed by a team of highly trained service

technicians

We will aspire to keep on exploring and enterprising, with

high-class products and high quality services creating more value

for our customers, creating a brighter future together.

Facial tissue Production Line

Packing & Delivery

Our Company

Toilet Paper Production Line

Deco Color Lamination Parts: