High Speed Toilet Paper Roll Packing Machine / Toilet Paper Wrapping Machine

Description

Semi Auto Toilet Roll Packing Machine / Toilet Paper Wrapping Machine adopting European electrostatic adherence technology, this machine is the most advanced toilet paper packaging machine in China. It is suitable for single toilet paper packaging.

Introduction

1 The toilet roll packing machine has the combined function of setting ,pronghorn, sealing,just artificially

placed rolls, automatic conveyor belt feed conveyor, bagging and sealing pronghorn once.Besides the

machine can be used with manual cutter.

2 The machine adopts advanced PLC computer programming control, liquid crystal display text

parameters,more accurate temperature control, more effective protection and high temperature resistant

tape of heat wire. It is easy to set up and easy to operate. Its sealing part is equipped with water

circulation cooling, sealing more solid, beautiful, and fast.

3 The machine is with a conveyor belt, just to put the roll of lust artificial standard pattern.The

machine automatically feed conveyor rolls, artificial bagging, pronghorn and sealing automatically. It has

advantages of faster speed, more economical labor; lower production costs and higher production

efficiency.

4 Packing speed:5-6 mention /min

5 The machine uses pronghorn form and transverse sealing sealing line for stubby-shaped rolls.

6 Main structure strong point:reasonable structure,stable performance and the material stronger which

make the machine more durable; moreover ,controlled parts of the main pieces is imported high quality

parts, the rest is the national standards of quality parts.

Specification

| Center distance | 192mm |

| Packing style | Pillow type(back to back) |

| Pillow type(back to back) | 60-120bags/min |

| Filling capacity | 500-7500g |

| Max film width | 450mm |

| Bagging size range | L150-250mm H120mm(please specify ) |

| Total power: | 3.2KW |

| Power supply | 220V 50HZ ( other voltage need order) |

| Power of main motor: | 0.75KW 0.2KW |

| Packing film | CPP,SPP or some vacuum alu-coated film. |

| Working noise | ≤78 |

| Pass percentage of finished bags | ≥97% |

| Sealing intensity | 15 (NEWTON/mm2 ) |

| Machine weight | 900kg |

| Machine dimensions | 4.32X1.15X1.75m |

Feature

1 . Adopting double-drive vertical sealing device, makes the vertical sealing stable, firm and neat

2 . Function of automatic stop at the fixed position is available

3 . PLC control makes the system reliable and easy maintenance

4 . Frequency control makes the operation easy and simple

Adopting photoelectric sensor to test the eye mark, non-contact point control, two-way tracking

Product Description

High Quality Facial Tissue Machine Paper Product Making Machinery

Features:

Facial tissue making machine working flow:The jumbo rolls which have been slit into the desired width are cut by the slitting cylinders,and then interfolded into interoverlapped rectangular facial tissue sheets.

This machine adopts independent servo motor drive,and automatic paper tension control automatic marking functings.It featurse of high speed,nice folding and easy operation.

1.Can order steel to rubber embossing rolls,pneumatically separated.

2.Wallboard rack and Machine running stability and extremely good and fast.

3.Pneumatic jumbo roll loading,pneumatic paper driving,stepless speed additionstment,and web tension control.

4.Equipped with roots type vacuum pump for stable running of the machine.

5.Make various products width as requirement.

6.Equipped with edge embossing unit to keep the plise together.

7.The machine will stop when the paper broken.It avoid waste caused by no paper or paper broken.

8.The web can be threaded on the machine by the two jog buttons,It's more safer and easier to thread the web.

1. Specification of Facial Tissue Folding Machine:

| Machine Model | SYM-190/6L (Other size to be specified) |

| Finished Products Unfolded Size | 95x(120-210)x2mm |

| Folding Products Size | 190x(120-210)x2mm |

| Raw Material Width | 1260mm |

| Raw Material Diameter | 1200mm |

| Raw Material Core Diameter | 76.2mm |

| Output Capacity (8 hours) | 2000-3000kg |

| Embossing Unit | Steel to rubber |

| Edge Embossing | Steel to steel edge embossing, independent pneumatic regulation |

| Slitting Unit | Pneumatic slitting |

| Main Servo Moter Power | 5.5kw |

| Unwind Frequency Motor Power | 1.5kw (2 units) |

| Vacuum System | 18.5 kw Vacuum pump (Taiwan Roots blower) |

| Pneumatic System | 3HP air compressor,Min. pressure 5kg/cm2PA (Provider by user themselves) |

| Driving System | Timing belt |

| Dimension | 5870x2800x2207mm |

| Weight | About 5 tons |

2. Specification of Single Channel Log Saw Cutting Machine:

| Designation | Parameter values |

| The length of the none cut off facial tissue | minimum 500mm |

| The Height of tissue | 30~130mm |

| Machine Speed | 20~150cut/min |

| Operating speed | 20~120cut/min |

| Round blade outer diamete | Φ610mm |

| Paper cutting circular knife top speed | 980R/min |

| Finished products specification | 70~300mm |

| Paper width | 70~110mm |

| Cutting Length | 70~300mm |

| Left-over Length | 20~65mm |

| Power | 11KW |

| Power supply | 380V 50Hz |

| Air source | 0.5~0.8MPa |

| Machine Size | 4600*1700*2500mm |

| Weight of machine | 2300~2600kg |

| Brake | Parameter setting (auto/manual) |

| Stepping sharpening knife | Parameter setting (auto) |

| Pneumatic sharpening knife | Parameter setting (auto/manual) |

| Blow air | without |

| The total pressure switch | Value (not) |

| Human-computer interface | DELTA |

| Frequency changer | |

| Servo Drive | DELTA |

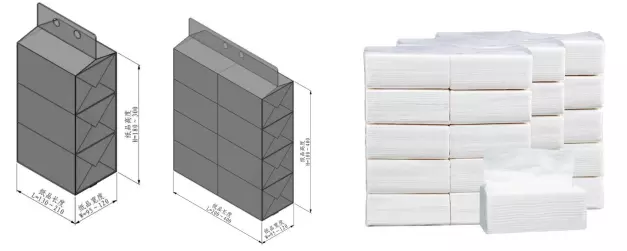

3. Specification of Facial Tissue Packing Machine:

1. Adopting packing way by wrapping, folding and sealing with compact structure, it makes the package look beautiful and the seal tightened.

2. Controlled by stepless speed regulation, touch screen and PLC, the display on the human-machine interface makes maintenance more simply.

3. Applied with auto-arranging feeding conveyor, it is convenient to connect the conveyor with automatic production line, saving the labor cost to the maximum.

4. It saves much packing material by means of photocell checking, servo tracking, and auto-stop of film feeding without product.

5. High automation, high profession, high efficiency and less trouble.

6. With wide packing size range, various packing sizes can be quickly interchanged.

| Tissue sizes: | L: 150-400mm W: 150-200mm H: 35-150mm |

| Packing speed: | 40-70 bags/min |

| Air supply: | 0.5-0.8MPa |

| Machine weight: | 3300kg |

| Outer dimensions (LxWxH): | 5885x3560x1925(mm) |

| Heating power: | 3.6kw |

| Motor power: | 3.6kw |

| Packing size: | ≤230x190x100(mm) |

| Working noise: | ≤78dB |

| Packing film: | CPP |

| Power supply type: | 380V, 50Hz |

4.Specifications of Semi Automatic Two Outlets Multi Bags Packing Machine:

| Packing Size | ≤500x300x110mm (LxWxH) |

| ≥220x120x90mm (LxWxH) |

| Packing Speed | 10-20 bag/min |

| Gas Pressure | 0.5mpa-0.8mpa |

| Voltage & Frequency | 380V,50Hz,3Phase |

| Total Power | 0.8kw |

| Weight | 1000kg |

| Overall Dimension | 4900x1650x1280mm |

| Tissue paper bag (one row/two rows) | Tissue paper bag (one row/two rows) |

Packing & Delivery

Our Company